INNAPACK

About INNAPACK

Innapack (PT. Trimitra Indoplast Mandiri) is an LLDPE film based flexible packaging manufacturing based in Cikarang, West Java, Indonesia. Established in 2011, the Company initially operated as a trading company, and has since evolved to become a manufacturing business.

Innapack has been providing innovative, high quality and economic packaging solutions catered for a diverse industries, including food and beverage, house hold goods, pharmaceuticals, chemicals, personal hygiene, etc.

Quality Products & Extensive Offerings

We provide high quality, innovatively tailored flexible packaging products that focus on high customer service orientation. Innapack creates packaging solutions from LLDPE, CPP, OPP, PET, Nylon and Aluminum materials, which are processed into two product categories: General Packaging and Laminated Packaging.

High-grade Machines

To ensure high quality products, Innapack is equipped with modern high technology machinaries and equipment for printing, lamination and laboratory equipments.

Certified ISO 9001 & ERP

Innapack is an ISO 9001 certified company. We ensure that our customers get consistent, good quality products and services.

The factory adopting full ERP system to ensure traceability and accurate reporting.

Quality Products & Extensive Offerings

We provide high quality, innovatively tailored flexible packaging products that meets your need. With a high customer service orientation, Innapack creates packaging solutions from LLDPE, CPP, OPP, PET, Nylon and Aluminum materials, which are processed into two product categories: General Packaging and Laminated Packaging.

High-grade Machines

To ensure high quality products, Innapack is equipped with modern high technology machinaries and equipment for printing, lamination and laboratory equipments.

Certified ISO 9001

Innapack is an ISO 9001 certified company. We ensure that our customers get consistent, good quality products and services.

RECENT BUILDS

AMAZING MILESTONES

DIG IT.

MOVE IT.

BUILD IT.

Our Products

General Packaging

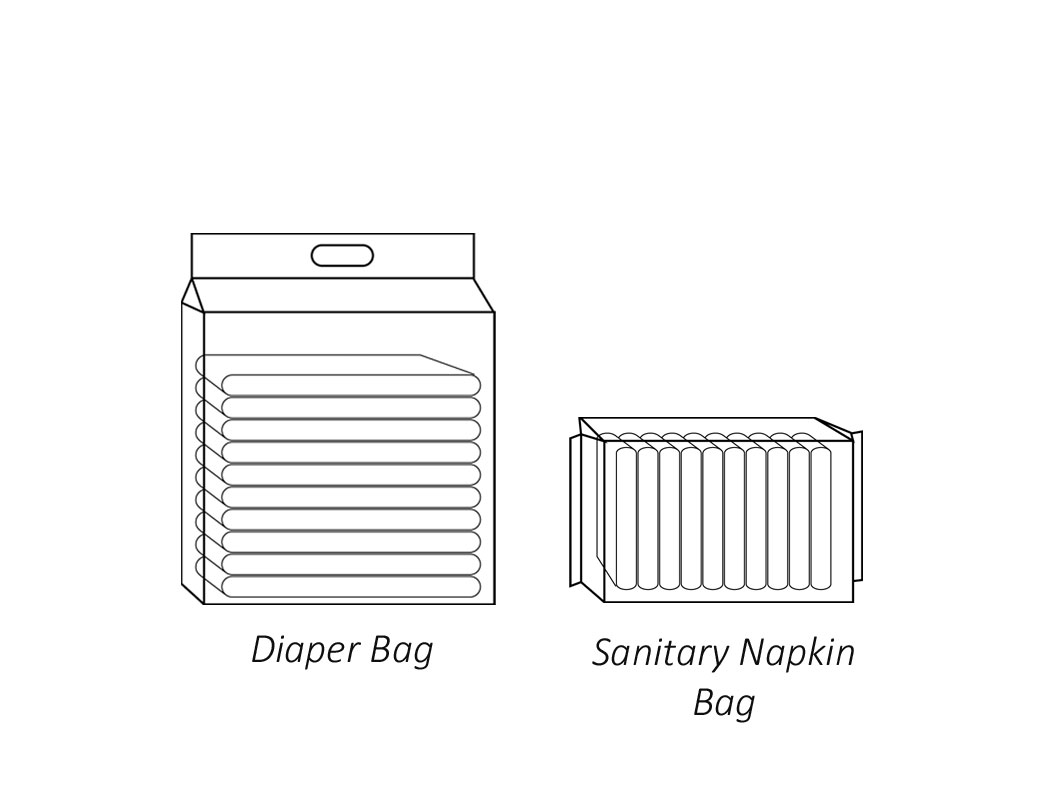

This is a single layer film that engages LLDPE, PVC, PP films into the printing and slitting process. Single layer film offers excellent solution for cost efficiency and flexibility. Popular application of single layer films include diaper, tissue, feminine hygiene. perforation bag, agricultural packaging, shopping bags.

- Can be printed up to 8 colors

- Good sealability

- Suitable for automated packaging machines

- Good anti block properties

- Used for bundling purposes

- Used with bottles, food cans, health and beauty products and household items

- Excelent clarity and Great sealibility

- Attractive shelf appeal

- Customizable colors on the inside and outside

- Excellent opacity to ensure content privacy

- Optional body pocket

- Permanent security seal

- Can be printed up to 8 color

- Good holding strength (does not droop)

- Attractive with glossy or doff finish

- Can be printed up to 8 colors

- Good holding strength (does not droop)

- Attractive with glossy or doff finish

A. Die Cut Handle Bottom seal bag

- Good holding strength (doesn’t droop)

- Can be printed on both side up to 8 colors

- Simple and economical

B. Soft Handle Bottom seal bag

- Elegant look

- Good holding strength (doesn’t droop)

- Can be printed on both side up to 8 colors

- Extra strength

- Strong puncture resistance

- Moisture barrier

- Substitute for paper sacks

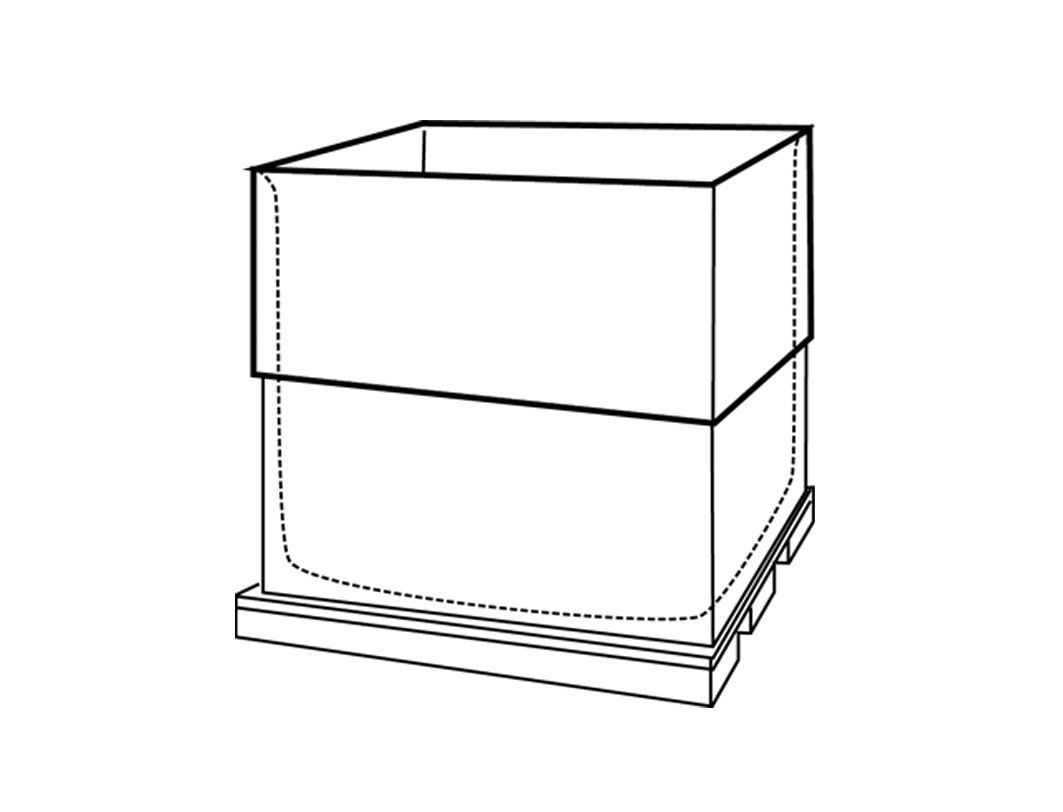

- Typically used to line the inside of boxes or drums, to protect content from air and moisture

- Excellent tear strength

- Easy to use

- Light weight

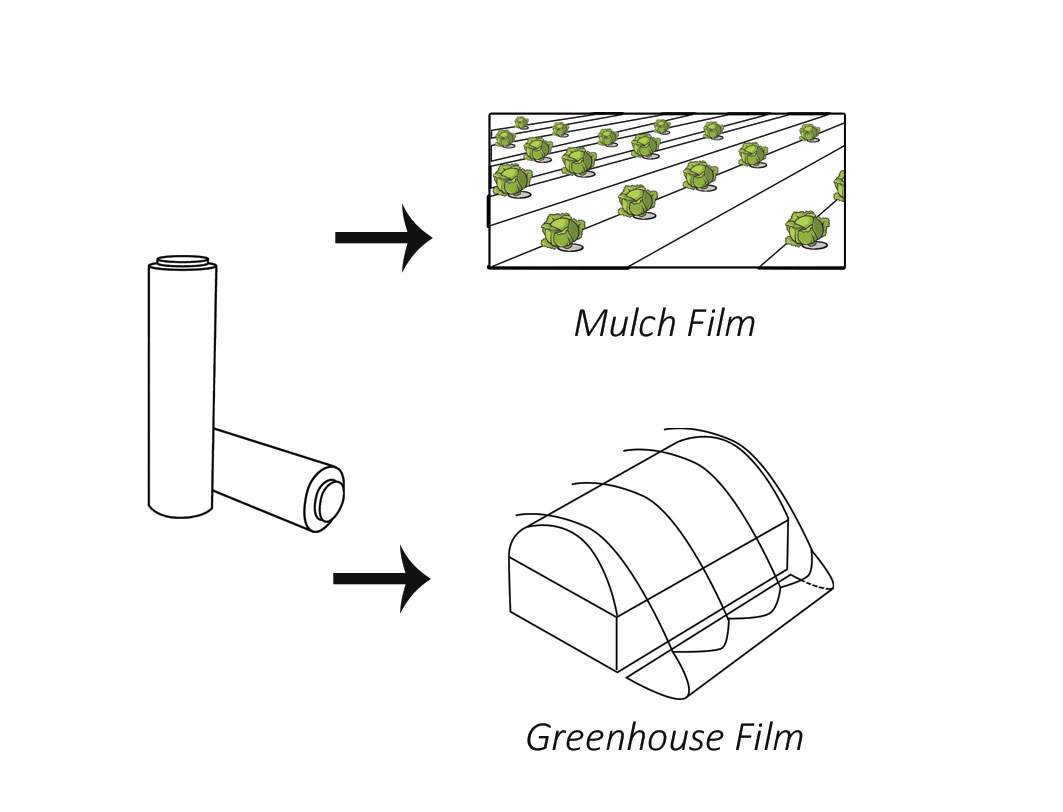

A. Mulch Film

- Used to eliminate weed growth and moisture conservation

- Optimum usage of fertilizer

- Available in one color (black) and dual color (black / silver)

- Optional UV stabilizer

- Excelent mechanical properties and tear strength

B. Greenhouse Film

- Excellent visible light transmission

- Strong mechanical properties to withstand hars weather

- Used to create all year round environmental growth

- Typical thickness is 200 micron, customizable width

- Optional UV stabilizer

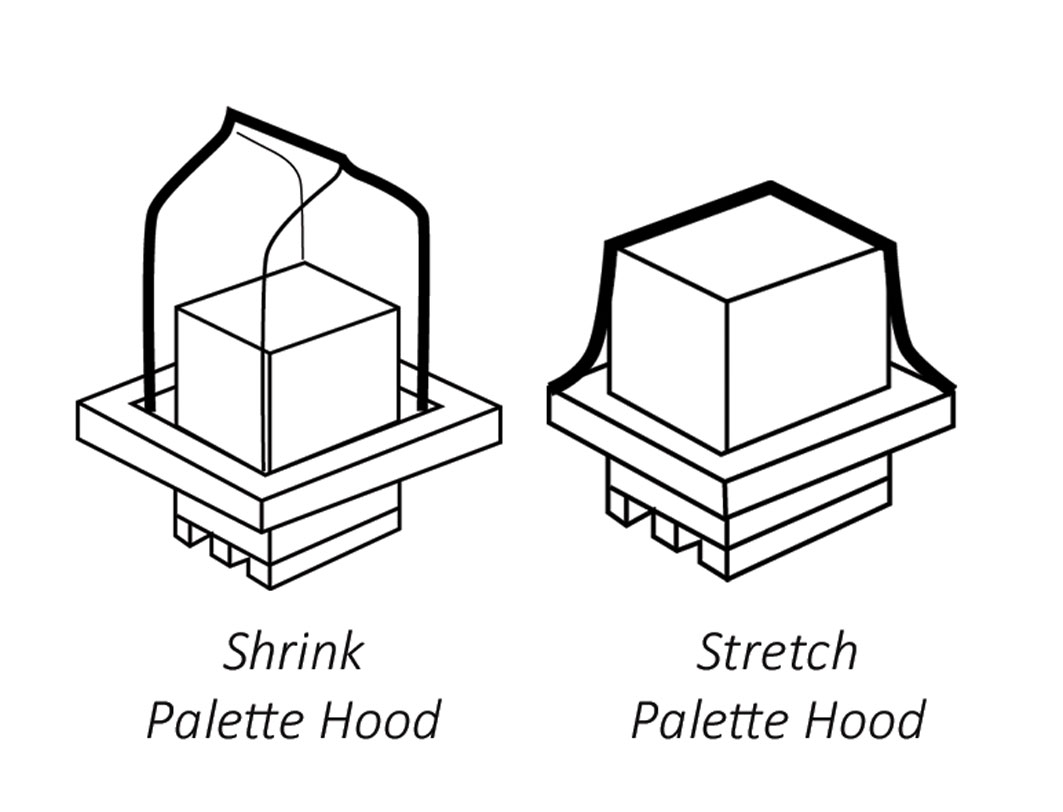

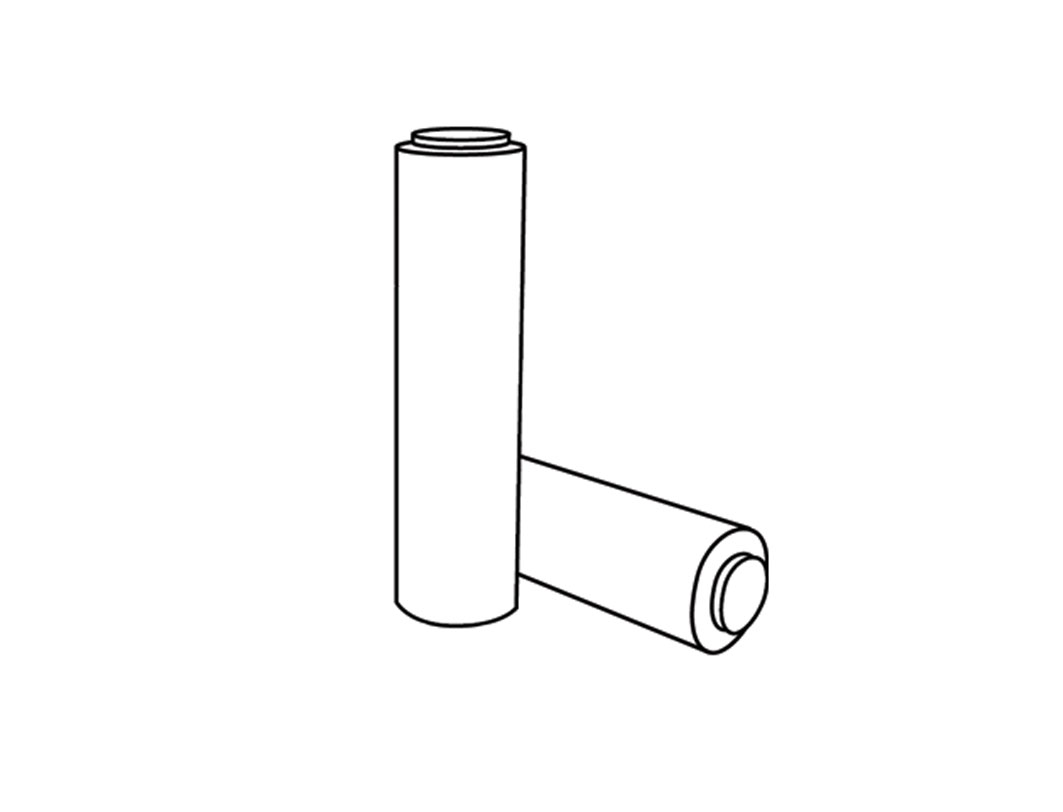

- Water proof

- Excellent load stabilization

- Great clarity allowing good visibility of loads inside

- Suitable for automated racking systems

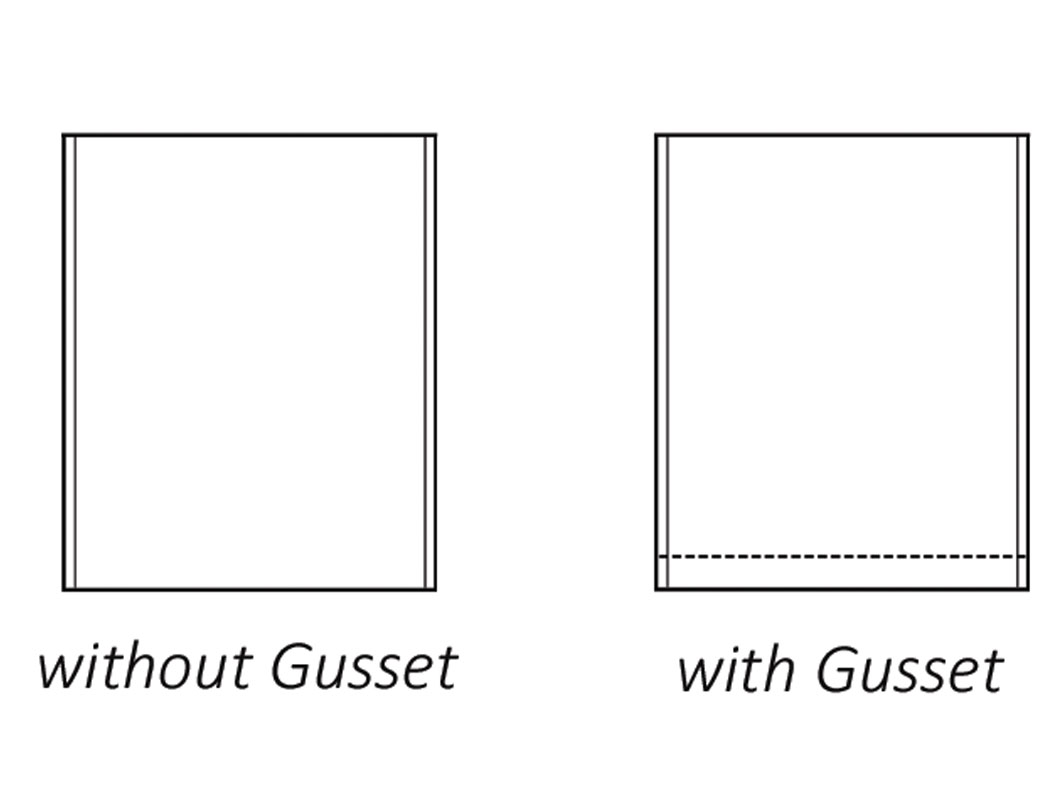

- General plastic pouch for various use including 3 side seal, bottom seal,

standing pouch, punch handle, reinforced handle, etc. - Can be printed up to 8 colors

- Can be printed on both sides

Laminated Packaging

This a multi layer film that combines a few materials, such as nylon, LLDPE, PET, CPP, OPP, PVC and engage them into the printing, laminating and slitting process. The multi layer films allow combining scuff resistant outer layer with a choice of inner layers having multiple barrier properties. The multi layer films enable high end graphics beneath a high gloss for better on-shelf appearance as well as packaging safety. On the other hand, the interior layer protects the products’ freshness.

Popular application for the multi layer films include packaging for food and beverage, household products, agricultural and health care industries.

- Very good adhesive strength

- Low seal temperature

- Good sealability

- Very good barrier

- Can be printed up to 8 colors

- General plastic pouch for various use including 3 side seal.

- Can be printed up to 8 colors

- Can be printed on both sides

Our Sustainibility Program

Innapack committed to making a positive impact on the environment, society, and economy through our sustainability program. Our business value is designed to promote responsible and sustainable practices through our partnerships, operations and supply chain.

Through research and development, Innapack has advanced to the usage of PCR LLDPE Film. Aside from its sustainability value, PCR LLDPE Film offers several other strong points as a product; its versatility, its cost effectiveness, and its durability. We are aiming to further increase both quality and quantity of PCR LLDPE Film usage.

Our goal of zero waste is to create a closed-loop system where resources are kept in use for as long as possible, and waste is minimized through the use of sustainable and circular systems.

Our installation of solar panels is one of our effort to create positive impact on the environment. By reducing our reliance on fossil fuels, we aim to significantly reduce our carbon footprint and contribute to a more sustainable future.

Biodegradable plastics are a type of plastic that can be broken down by microorganisms into natural substances such as carbon dioxide, water, and biomass. Our plastics are designed to degrade in the environment easily under exposure of sunlight, heat, moisture, or microbial activity.

OUR PRODUCTS

OUR BUILDERS

Matt Simpson

Field Supervisor

Rick Farris

Lead Plumber

Dave Connors

Expert Electrician